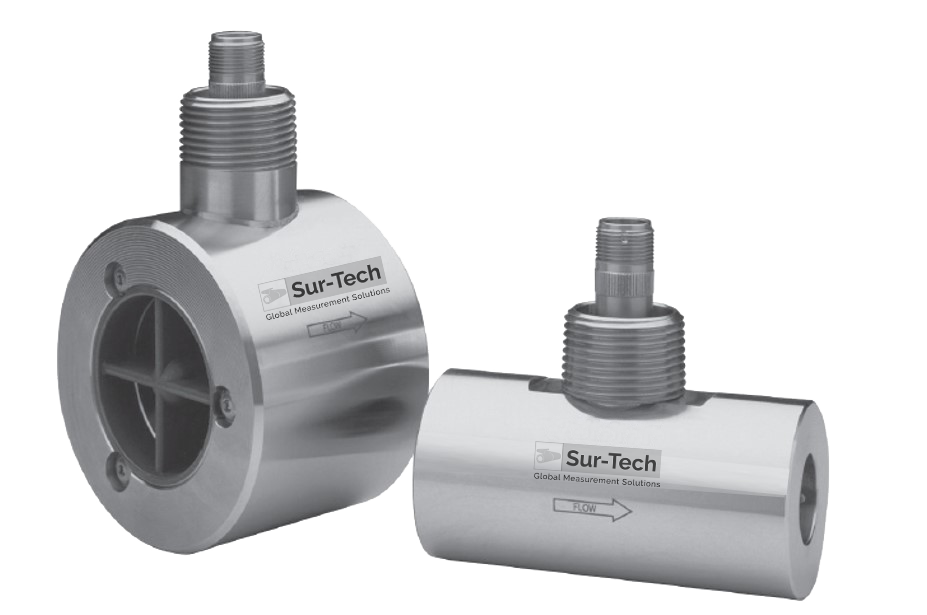

Wafer Turbine Flow Meter

The in-line turbine flow meter was developed for liquid applications where accuracy and dependability are needed.

Our stainless-steel body incorporates a helical turbine with tungsten carbide shaft and bearing. It provides an efficient, long service life and a cost-effective solution for your measurement requirements.

Simple in design and construction, using modified upstream and downstream flow straighteners for a high degree of flow accuracy. It’s between-the-flange design eliminates the need for mating flanges, requiring less space in the flow line, lowering costs for easy, one-man installation.

The meter produces a sine-wave signal proportional to its volumetric flow rate. With optional electronics, this flow meter provides local flow rate and volume totalization and interfaces with most instruments, PLCs and computers.

Features

| ORDERING INFORMATION | |

| Materials Of Construction | Body and internal wetted parts: 316L stainless steel Bearings: Tungsten carbide Turbine: CD4MCU stainless steel Shaft: Tungsten carbide |

| Accuracy | ±1% of reading for 7/8 in. and larger meters ±1% of reading over the upper 70% of the measuring range for 3/8 in., 1/2 in. and 3/4 in. meters |

| Repeatability | ±0.1% |

| Calibration | Water; NIST Traceable Calibration Certificate available, consult factory for details |

| Size Ranges | 3/8″ to 10″ |

| Pressure Rating | 150-900 ANSI |

| Operating Temperature | –150…350° F (–101…177° C) standard Temperatures to 450° F (232° C) with high-temp pickup, consult factory for details |

| End Connections | Wafer-style ASME/ANSI B16.5-1996 |

| Approvals | For Explosion proof models only: Class l Div 1 Groups C,D; Complies to UL 1203 and CSA 22.2 No. 30 Met Labs File No. E112860 |