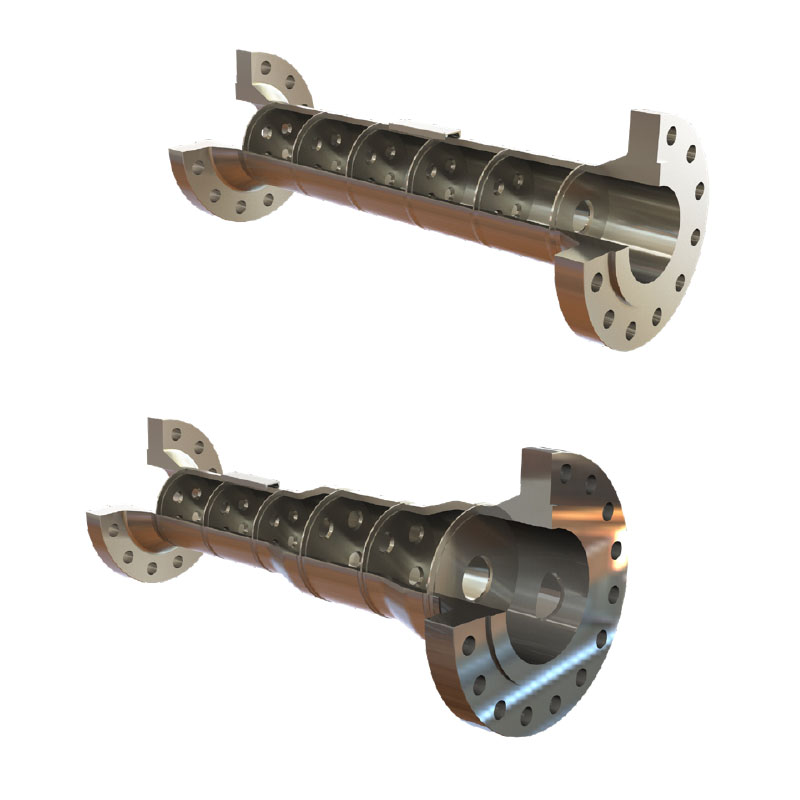

Restriction Orifice Multi Plate Spools

Restriction Orifice Multi Plate Spools are used as a means of controlling line pressure in systems using pressure critical componentry when a single Restriction plate is not adequate. The design is based on a series of Restriction Orifice Plates welded into a custom made pipe spool which creates an overall pressure drop and in turn provides the required downstream pressure.

Each restriction orifice is calculated and designed taking into account the medium characteristics, the pressure loss and the process data into account.

The use of multi-holed plates is often used if the noise at each plate is above the industry accepted 85dB.

For liquid restriction applications the spool is normally the same line size. For gas restriction applications the multi plate spool is sometimes required to expand across pressure drop stages due to the expansion of the gas under the reduced pressures.

Features

| ORDERING INFORMATION | Part number format for ordering is as follows; FACING-INLET-OULET-ANSI-SPOOL MTL-PLATE NO.-PLATE MTL |

| INLET SIZE | 0.5” – 24” (other sizes available upon request) |

| OUTLET | 0.5” – 24” (other sizes available upon request) |

| ANSI | 150, 300, 600, 900, 1500, 2500 |

| SPOOL MTL | CS = Carbon Steel 304 = 304 St. Steel 316 = 316 St. Steel D = Duplex SD = Super Duplex M = Monel I = Inconel |

| PLATE NO. | Number of plates in spool |

| PLATE MTL | 304 = 304 St. Steel 316 = 316 St. Steel D = Duplex SD = Super Duplex M = Monel I = Inconel |

| WORKED EXAMPLES | |

| STRFROMPS-4-4-900-5-316 | RF Restriction Orifice Multi Plate spool 4” inlet x 4” outlet 900# with Carbon Steel spool and 5 x 316 SS plates |

| STRTJROMPS-4-10-1500-5-CS-316 | RTJ Restriction Orifice Multi Plate Spool 4” inlet x 10” outlet 1500# with Carbon Steel spool and 5 x 316 SS plates |