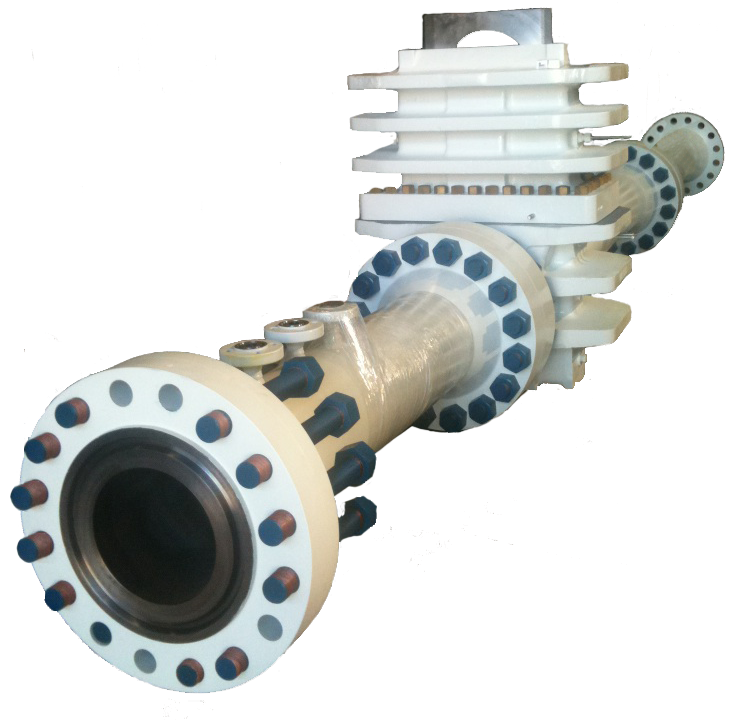

MRST – Meter Run

Meter Runs are available in a range of standard line sizes and configurations with optional materials available upon request.

Regardless of the primary measurement technology, there is always a need for a specially produced meter run which offers ample space to condition the flow prior to measurement and to allow for other process instruments to measure up and downstream of the primary meter.

Each meter run is designed in strict accordance to the relevant design codes. Our experience involves the design, fabrication and execution of these specialist metering pipe runs.

Features

| SPECIFICATIONS | |

| Materials of Construction | Body: 316 Stainless Steel Rotor: CD4MCU Stainless Steel Rotor Support: 316 Stainless Steel Rotor Shaft: Tungsten Carbide |

| Turndown Ratio | 10:1 |

| Flow Accuracy | ±1% of reading for 7/8 in. and larger meters ±1% of reading over the upper 70% of the measuring range for 3/8, 1/2, and 3/4 in. meters |

| Repeatability | ±0.1% |

| Calibration | Water (NIST traceable calibration) |

| Pressure Rating | 5000 psi max. |

| Turbine Temperature | -150…350ºF (-101…177ºC) |

| End Connections | NOT, BSP, Victaulic®, flange, hose barbed |

| Certifications | CSA Class I Div 1, Groups C & D Class II Div 1, Groups #, F & G: intrinsically safe* CSA Class I Div 1 Groups C & D; complies to UL 1203 and CSA 22.2 No. 30 Met Labs File No. E112860 (for explosion proof models only) |