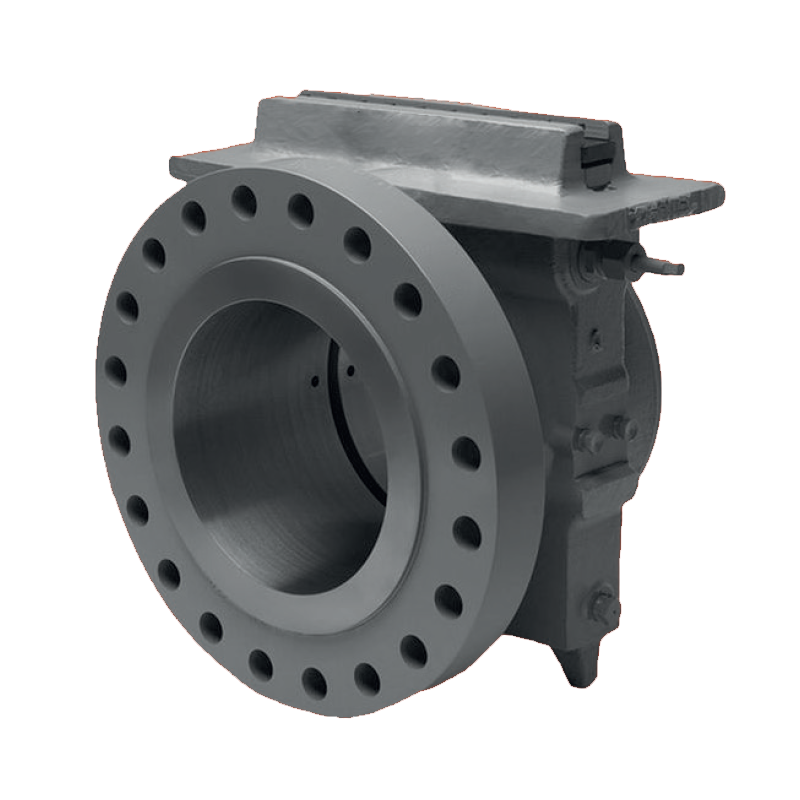

Single Chamber Orifice Meters

Single Chamber Orifice Meters are available in a range of standard line sizes and configurations with optional materials available upon request.

Single Chamber Orifice Meters are used for flow measurement applications and are used to aid orifice plate inspections without the need to break the flange pipeline integrity, albeit a line shutdown and depressurisation is required. The plate is housed in a carrier ring with seals to mitigate any process bypass of the plate causing mismeasurement.

Economical and easy-to-use, this low maintenance flow measurement device simplifies the plate inspection and removal process without the need for flange separation.

Features

| ORDERING INFORMATION | Part number format for ordering is as follows; SIZE-ANSI-SCH-CODE-CONFIG-FACING-QTY&TAP-MTL |

| Size | 2” – 24” (other sizes available upon request) |

| SCH | Pipe schedule or custom ID |

| ANSI | 150 – 2500 & up to 10,000 PSI |

| Code | I = ISO 5167 A = AGA 3 BX = API Groove C = Customer specific |

| Configuration | W = Weld x Weld F = Flange x Flange FW = Flange x Weld |

| Flange Facings | RF = Raised Face RTJ = Ring Joint BX = API Groove C = Customer specific |

| QTY of Tapping pairs | 2 (one tapping pair per meter side) 4 (two tapping pairs per meter side also known as Telemetry taps) Note: telemetry taps not available for ISO 5167 orders) |

| TAPPING | N = NPT-F F = Flanged (ANSI & facing to suit line flange) C = Custom |

| MATERIAL | WC = High Temp C. Steel LC = Low Temp C. Steel 316 = Stainless Steel D = Duplex SD = Super Duplex M = Monel |

| WORKED EXAMPLES | |

| STSC-4-600-80-A-FW-RF-4-N-D | Single Chamber 4” 600# Sch.80 Flange x Weld RF, AGA 3, 4 pairs of NPT-F taps in Duplex |

| STSC-8-1500-160-I-FF-RTJ-2-F-LC | Single Chamber 8” 1500# Sch.160 Flange x Flange RTJ, ISO5167, 2 pairs of flanged taps in Low Temp Carbon Steel |