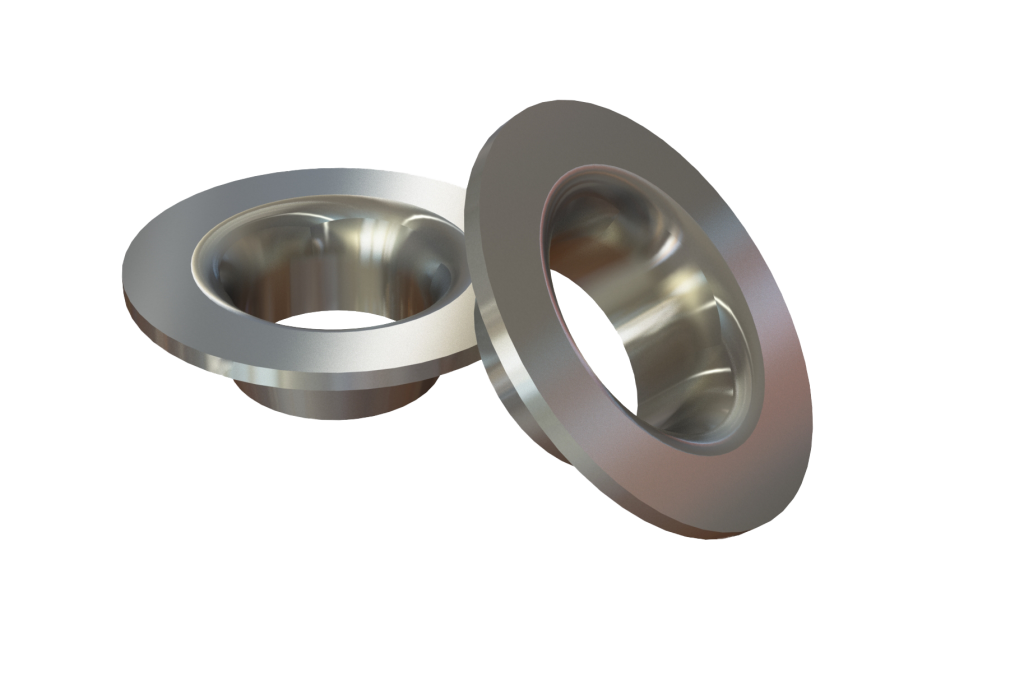

Flow Nozzles

Flow Nozzles are reliable, easy to use and maintenance-free flow meters. They are particularly well suited to the measurement of high velocity and abrasive process in gas, steam and liquid flows. Used in multiple industries with a wide variety of design options in accordance to ISO 5167-3 and ASME MFC3.

Features

| ORDERING INFORMATION | Part number format for ordering is as follows; SIZE-SCH-ANSI-CONFIG-FACING-FORM-QTY&TAP-MTL |

| Size | 0.5” – 24” (other sizes available upon request) |

| SCH | Pipe schedule or custom ID |

| ANSI | 150 – 2500 & up to 10,000 PSI |

| Configuration | W = Weld x Weld F = Flange x Flange H = Hub x Hub |

| Flange Facings | RF = Raised Face RTJ Ring = Joint BX = API Groove C = Customer specific |

| Form | I = ISA 1932 Nozzle L = Long Form Nozzle V = Venturi Nozzle |

| QTY | Number of pairs of tappings or if annular quantity is 1 pair |

| TAPPING | T = Thread-o-let F = Flanged A = Annular Ring C = Custom |

| MATERIAL | C = Carbon Steel 316 = Stainless Steel D = Duplex SD = Super Duplex M = Monel |

| WORKED EXAMPLES | |

| STNOZ-24-120-900-F-RTJ-V-2T-316 | 24” Sch.120 900# Flanged (RTJ) Venturi Nozzle with 2 pairs of flanged taps in 316 St. Steel |